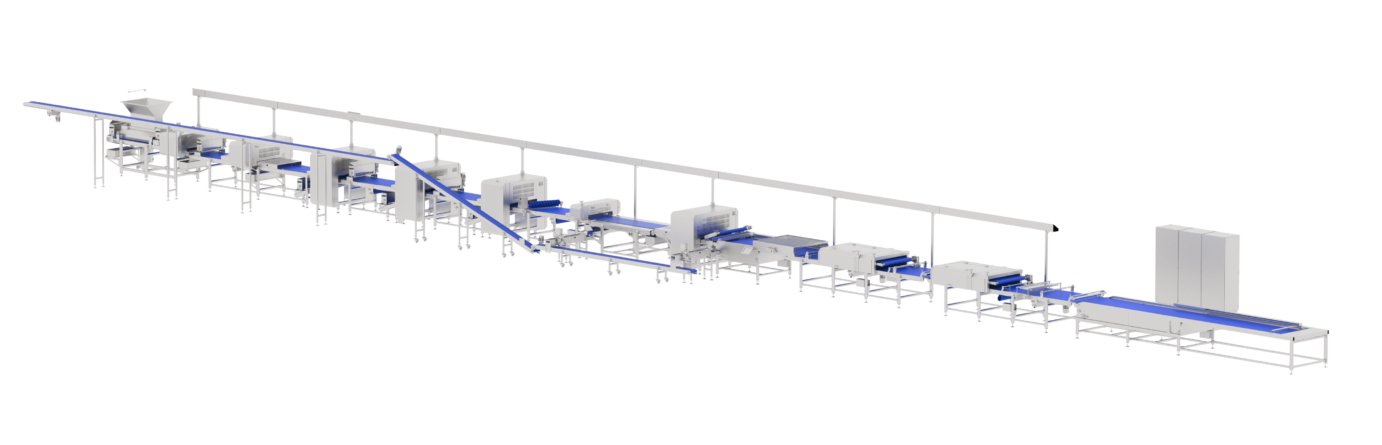

Gaudí Plus

Custom-designed multiproduct line for hydrated doughs.

Gaudí Plus is a fully modular laminating system, designed to adapt to a wide variety of laminated, molded, and rolled products, including very thin pieces with optimal quality and crumb structure.

It offers maximum versatility in product sizes and weights, allowing the production of pointed, round, hexagonal, and other shapes.

Optional rolling/molding module and seed module available.

Ready to work with gluten-free doughs.

L: 10.800 mm

W: 1.600 mm

H: 1.700 mm

Chunker

Feeds the dough precisely and uniformly. It reduces splices by up to 40%. It includes an adjustable laminating roller for dough uniformity, a 90° tilting hopper for easy cleaning, and a removable flour duster with speed inverter.

Cross sheeter

Large roller which helps to spread the dough and get it wider.

Multiroller nº1

Gradually reduces dough thickness through a series of large rollers.

Multiroller nº2

Performs a finer reduction of dough thickness, delivering a higher degree of lamination while maintaining dough integrity.

Laminating roller

Laminating roller for optimal final calibration of the dough.

Cutting station

Trims dough sheet edges and optionally scores portions.

Separator belts

Separates dough lanes to avoid tension and ensure straight, uniform flow.

Servomotor guillotine

Executes the final cut of the laminated dough sheet to length.

Scrap remover belt

Eliminates dough scraps between portions to ensure clean cut zones.

Retractable spacing belt

Spaces dough pieces without stopping the line, increasing efficiency and automation.

Double molding system

Performs rolling and shaping to create rustic or traditional-style breads.

Retractable placing system

Places dough portions onto trays or boards with high accuracy. Synchronizes with spacing belt and downstream baking logistics.

Electrical cabinet

Centralized control and distribution of electrical components across the line. Designed for accessibility, safety, and integration.